Weld Procedure Development PQR & WPS

We develop and optimise welding procedures for a wide range of materials to ensure code compliance and high value, fit for purpose weld procedures.

Welding Procedure Specification’s (WPS) are an essential requirement for code compliance and quality work for companies working to any pressure and structural code. They are the foundation that ensures a weld can repeatably create the required mechanical properties in the joint using known variables.

By understanding what your specific job requirements are, Sharp Eye Engineering (SEE) will work with the client to draft a preliminary Welding Procedure Specification (pWPS) that includes the appropriate variables (ie; materials, welding consumables, joint preparation and position) that can be used to complete the specific task, and at the same time provide the maximum range qualification for high value.

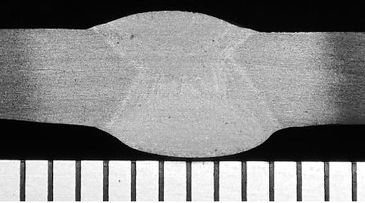

Procedure Qualification Record’s (PQR) are a requirement for all WPS’s that require mechanical testing and are the backbone for the WPS. They are a direct record of all the code required variables during welding of a coupon as described in the pWPS. Sharp Eye Engineering is capable of coordinating and supervising the PQR welding and testing, with the welding optionally done at the client’s facility using in-house labour and material or completing the PQR entirely offsite.

Welding Procedure Specification’s (WPS) are written from the result’s of the PQR and the testing conducted in accordance with the allowable variables of the code nominated.

Welding codes can range from Australian to international codes depending on your requirements. We can provide the appropriate WPS/PQR to comply with the code you are working to with experience in AS3992, AS1554, AS1665, ASME IX, ISO 15614.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.

.png/:/rs=h:155,cg:true,m/qt=q:100/ll)

.png/:/rs=h:104,cg:true,m/qt=q:100/ll)